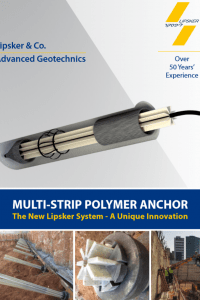

Multi-Strip Polymer Anchor- Lipsker system

Development, Manufacture and Execution

The Multi-Strip Polymer Anchor for use in retaining walls, tunneling and nailing, is a unique, innovative development from the Lipsker Company.

Over a period of five years, Lipsker used polymer strips and bars from a wide range of manufacturers to develop and test the optimal polymer ground anchor.

Through that R&D program, Lipsker developed a unique, patent protected anchor and tensioning system with maximum load capacity for standard drill hole diameters. These anchors, which have no couplers and no steel parts, comprise up to eight polymer strips along its entire length.

The Lipsker Polymer Anchor provides a complete solution for sites where execution constraints preclude the use of steel anchors.

Lipsker Polymer Anchors have been installed successfully at three sites along the route of the Tel-Aviv new Metro line.

Advantages of the Lipsker Polymer Anchor

• The structure of the Polymer Anchor is designed for use in standard drill holes. Polymer Anchors comprise up to eight polymer strips providing maximum strength and load bearing capacity.

• This anchor comprises polymer strips along its entire length; it has no couplers or steel parts.

• Polymer strips are supplied by the manufacture as a reel, which is cut to fit as required. Large quantities can be shipped at low cost.

• The polymer strips are coated with a special material, which improves grip on the soil using cement grouting.

• Anchor installation does not interfere with tunneling using TBM or any other tunneling system.

• Polymer anchors do not impede excavation work in adjacent plots.

• When the anchor is no longer needed, it remains in the hole. No dismantling or removal work is required.

• Polymer anchors are protected against corrosion and aggressive materials in the soil and they are not sensitive to electromagnetic fields.

• Polymer anchor installation is simple, without any need for a crane or lifting equipment.

• Tensioning strength for polymer anchor strips is twice that of steel and polymer strips weigh 75% less than steel.

Polymer Anchors Installed in Israel

Lipsker & Co. is Israel’s sole manufacturer of polymer anchors without any steel parts, used to anchor retaining walls. More than 1000 Lipsker System Polymer Anchors tested up to 90 tons have been installed at major projects in Israel’s central region:

• Galei Gil Launching Shaft for the Tel-Aviv Metro red line in Ramat Gan – 60 ton service load anchors.

• Em Amoshavot Launching Shaft for the Tel-Aviv Metro red line -70 ton service load anchors.

• Midtown Project at 144, Begin Road, Tel Aviv - 73 ton service load anchors. A total of 723 polymer anchors will be installed at this site.

• Tsamarot Dan Tower at 105, Jabotinski Street, Ramat Gan –65 ton service load anchors.

• The Metromol Bulding at 2, Oppenheimer Street, Rechovot – 55 ton service load anchors.

• Rubinstein twins-60 ton service load anchors

Polymer Anchor Strip Manufacturer: The Sireg Company

The Sireg Company was founded in Italy in 1936. Since then, Sireg has grown in both size and reputation. Today, Sireg is a world leader in the manufacture of plastic, fiberglass and polymer products for use in geotechnical and civil engineering applications.

Sireg Company products have been installed in major projects in many countries worldwide. Lipsker is the sole representative of Sireg in Israel.

| Recommended Load Capacity – 9 x 40mm Strips |

| Number of Strips | Service Load (ton) | Test Load (ton) |

| 4 | 40 | 50 |

| 6 | 50 | 65 |

| 8 | 70 | 90 |

Innovators, Designers and Consultants

At your service – Lipsker provides smart solutions using polymer anchors at sites where steel anchors cannot be used.

Contact us and our engineers will get back to you as soon as possible.